Stiffness and Strength are basic terms in structural engineering. One might feel they are similar but they have certain differences. And these differences are key in understanding these terms.

It is safe to assume that Stiffness and Strength mostly govern Structural Engineering. All of Structural Engineering can be taught, in one way or another, based on Stiffness. Hence, understanding these terms is very essential for a Structural Engineer.

Page Contents

Stiffness and Strength

In general, all the textbooks define Stiffness as the resistance to deformation. This is absolutely true. But this doesn’t define stiffness completely. On the other hand, strength is the ability of the material to take the load or support it without failure.

In other words, Strength measures how much stress the material can handle before permanent deformation occurs, whereas the stiffness measures the resistance to elastic deformation. We shall see each term in detail to understand better.

What is Stiffness

We talked in large about Young’s Modulus and Area Moment of Inertia in our previous posts. Together, these terms make up Stiffness. These are the stiffness terms of material and cross-section area respectively.

Stiffness governs loading taken by a Structural Element i.e., Force flow in a structure. Although it is not the only parameter that governs it.

To understand this point, let us imagine a building. We all know that building, like any structure, is a combination of different structural and non-structural components/elements.

External loads acting on a building has to be transferred to the soil via these structural elements.

Imagine two columns of the same material (Concrete of the same grade) in that building. As the material is the same, it’s Young’s Modulus (E) is same. Assume the cross-sectional area of these two columns is different. Hence, Area Moment of Inertia (I) will be different.

Now the load taken by these columns are NOT the same. As the Stiffness of one column is different than the other. The column with higher stiffness takes up more load than the column with lower stiffness.

In other words, forces/loads taken by a structural element depends on their stiffness. Remember, it is not the only parameter. For example, Support conditions also govern the force flow and stiffness also depends on support conditions.

How is Stiffness Calculated

Now, we can redefine stiffness as the ability of a material to distribute a load and resist deformation. From this, we can get understand that stiffness depends on Forces and Deformations.

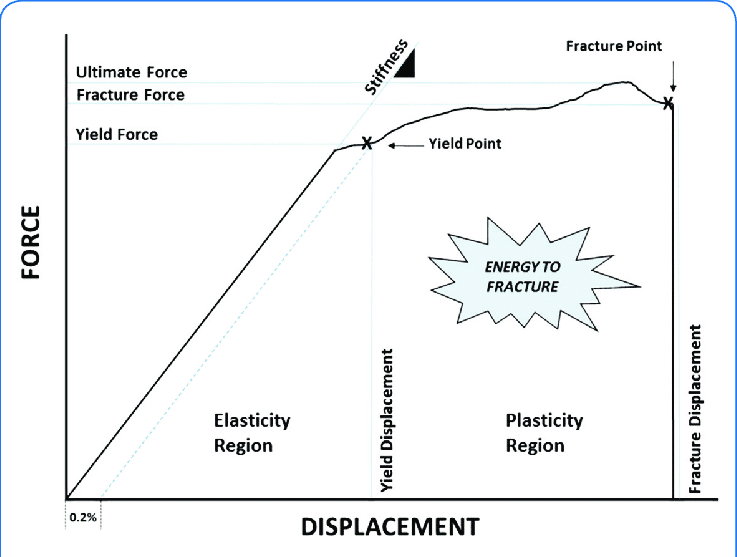

If we draw a curve for force and deformation, the initial slope of this curve is Stiffness. Remember, Young’s modulus is the initial slope of Stress and Strain Curve.

Mathematically, we can say that Stiffness is force per unit deformation. It is denoted as K.

$$K = F/δ$$

This is true for an elastic body with a Single Degree of Freedom (DOF).

Types of Stiffness

Depending on the type of deformation, stiffness can be classified as different types.

Axial Stiffness

When you pull (or push) a member along its axis, it creates deformation. Resistance towards axial deformation due to the applied tension (or compression) is called Axial Stiffness.

Mathematically, K = AE/L where AE is called as Axial Rigidity.

Rotational Stiffness

When a moment is applied to a member, it creates a rotation. The ability of a material to resist rotation caused by applied Moment is called Rotational Stiffness and it is given by K=M/θ.

Lateral Stiffness

The ability of a body to resist lateral deflection when a lateral force is applied. This is also called as Storey Stiffness, wherein the lateral deflection is storey drift and lateral force is storey shear.

Torsional Stiffness

The moment applied about the longitudinal axis of the member creates Torsion. Torsion, in turn, creates twisting of the member.

The ratio of applied Torsional moment to the angle of twist is called Torsional Stiffness. K= GJ/L. G is Shear Modulus and J is Polar MOI. GJ is called as Torsional Rigidity

Bending Stiffness

The resistance of a member against bending. For beams, flexural rigidity is considered as bending stiffness.

Shear Stiffness

The ratio of Shear force to Shear deformation.

Rigidity is a structural property that integrates both material property and Geometric/Sectional Property. Rigidity is the ability of a material to not bend when a force is applied.

You might have heard about Strong Column – Weak Beam concept in Frames. As a structural engineer, you should ensure that columns are stronger than beams. This can be possible by increasing the stiffness of a column.

In-Plane and Out-Plane Stiffness

Unlike Young’s modulus, stiffness varies along the planes as Moment of Inertia varies. This can be better understood by an example.

Consider a Wall. It is easy to topple the wall by pushing the wall on its largest face as shown. But try doing it on the other face.

When you are pushing a wall on its largest face, you are actually pushing it out of the plane of a wall. The stiffness corresponding to this out-plane is called Out-Plane Stiffness.

When you are pushing on the smallest face, it is In-Plane. Wall can fail in shear in this but it is not easy to topple the wall. And the stiffness corresponding to this is called In-Plane Stiffness.

From this, we can understand that Walls have More In-Plane stiffness than Out-Plane stiffness. Hence all Shear walls are to be placed so that the lateral loads can be In-Plane.

This way you can increase the stiffness of Shear Wall, thereby reducing loads taken by your building. In case of severe Earthquakes or any other lateral loads, your shear wall would fail first and building can get away with small deformations.

What is Flexibility

Flexibility is rather very easy and self-explanatory. It can be defined as the inverse of Stiffness. Instead of resisting the force, the body tends to move/bend along the force.

In other words, if a body is stiff then the deformations are small. If a body is less stiff (flexible) then deformations are huge.

You might think, you want a stiffer member in all the cases? You would rather not. Stiffer members fail suddenly, more like a brittle failure. No prior warnings. As a Structural engineer, you need to avoid this failure as much as you can.

To understand this, think of two trees standing in a cyclone. A huge tree with a large trunk has more stiffness and naturally resist winds with all its might. It fails suddenly when it cannot resist wind anymore. This is the reason why many trees fell down during cyclones.

Now think of a lean tree. It naturally takes the direction of the wind and bend. Even during severe winds, you might feel that this tree can fall any minute, but still, it stands there even after a cyclone.

We need our structures to be flexible but control the deformations. One way to do this is to increase the stiffness of certain structural elements, like a shear wall, to make your structure safe and decrease the deformations.

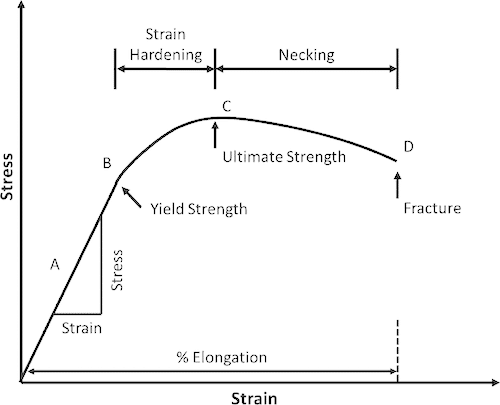

What is Strength

We can define this more easily with a stress-strain curve. Maximum stress taken by a material is called Strength. In other words, the maximum load taken by the material before its failure is called Strength.

Strength is classified into many types based on its failure.

- Yield Strength The load after which the plastic behaviour or permanent deformation starts in a material. In other words, the load above which the material cannot regain its original shape is called Yield Strength. When a material yields, the stiffness of that material is reduced.

- Ultimate Strength Maximum/peak load that a material can take. This is higher than Yield Strength in many cases. For brittle materials, this value is close to that of yield strength.

- Rupture Strength The load pertaining to the failure point is called Rupture Strength. This can be smaller than Ultimate strength (mostly true for many materials) and the process of loss of strength from ultimate to rupture is called Softening.

Apart from this, there is another classification of strength.

- Tensile Strength The ability of a material to withstand tensile (elongation) loads without undergoing permanent deformation.

- Compressive Strength The ability of a material to withstand compression loads.

- Shear Strength The ability of a material to withstand shear force.

Significance of Stiffness and Strength

- As previously told, stiffness governs structural engineering in one way or another.

- Stiffness is a property which is directly related to two of the governing parameters, Forces/Loads which are inputs and deflections which are direct outputs. Hence it directly governs a Structure.

- It is important in the design of elements and controls their deflection.

- It governs the loading taken by a structural element in a structure.

- Position and orientation of the elements are governed by stiffness.

- Stiffness is very important when it comes to the design of tall buildings, so as to avoid the collapse of buildings by creating a high stiffness member like Shear walls, Cores, Tubes etc.

- Strength is important for designing the dimensions and the materials to be used for construction.