A structural engineer while designing steel members definitely would have come across something like plastic, compact, semi-compact, slender section in IS 800-2007. These are the different types of classification of steel cross sections.

We shall now learn about that classification and its importance in design. To make this much easier, we need to know about different terms and parameters that govern the steel cross sections’ classification.

Page Contents

METHODS OF ANALYSIS

Generally, there are two methods of analysis in steel structures

ELASTIC ANALYSIS

The Elastic design method, also termed as allowable stress method, is a conventional method of design based on the elastic properties of steel.

This method of design limits the structural use of the material up to certain allowable stress, which is well below the elastic limit.

PLASTIC ANALYSIS

In the Plastic design method, the ultimate load is taken as the design criterion rather than the yield stress. The term plastic has occurred because the ultimate load is found in the plastic range.

This method is generally preferred for Steel Structures as the strength of steel beyond the yield stress is fully utilized.

PARAMETERS INFLUENCING THE CLASSIFICATION

LOCAL BUCKLING

Steel cross sections consist of an assembly of thin plate elements. When they are subjected to large compressive stresses, if the thin plates are too slender, then it may buckle even before the full strength of the member is attained.

This phenomenon is called Local buckling and this happens when the width to thickness ratio is too large. Hence, to avoid this, the width to thickness ratio needs to be limited.

MOMENT REDISTRIBUTION

In the Plastic Analysis, the material is fully utilized beyond the yield stress. This can be achieved by moment redistribution.

Under loading, yielding occurs initially at some points (generally at supports), where the section starts rotating under a constant moment. To counterbalance the additional load, the moments will be distributed to other portions of the section which are still elastic (generally from supports to span).

This process is known as Moment Redistribution. This process continues until a mechanism forms which leads to its collapse.

DIFFERENT TYPES OF STEEL CROSS SECTIONS

As per IS 800-2007, the classification of the steel cross sections depends on the load that the section can carry before failing, local buckling, moment redistribution capacity and the width to thickness ratio of the sections in consideration.

The steel cross sections are mainly classified into four types based on the above criteria as per IS 800-2007.

1. Plastic section

2. Compact section

3. Semi-compact section

4. Slender section

So what are these sections?

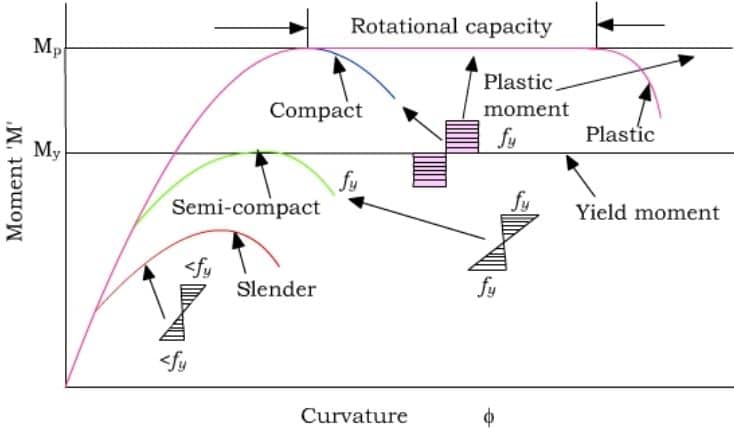

This can be better understood by the graph shown here. The following can be inferred from the graph about the sections.

1. Plastic Section

The plastic section is capable of developing plastic moment and plastic hinges with sufficient rotation capacity without local buckling. These sections can take load until a failure mechanism, which is beyond the plastic moment, by redistribution of moments.

2. Compact Section

These sections can develop the plastic moment but the plastic hinge rotation capacity is inadequate because of local buckling. Hence, it fails even before developing a plastic mechanism. There is no redistribution of moments here.

The width to thickness ratio of plate elements is greater than that of Plastic sections.

3. Semi-Compact Section

The extreme fibre stress attains yield stress but cannot develop plastic moment. The maximum moment it can attain is Yield Moment. The member fails by local buckling even before it forms a mechanism.

The width to thickness ratio of plate elements is greater than that of Compact sections.

4. Slender Section

Even the extreme fibre does not reach yield stress in these sections. The width to thickness ratio is very high that the elements buckle locally even before reaching yield stress. These sections can not attain the yield moment.

POINTS TO REMEMBER

1. Local buckling is discussed as a phenomenon controlling the strength of compression and bending members.

2. The cross-sections are classified into plastic, compact, semi-compact and slender depending upon their moment-rotation characteristics.

3. The limits on the width-thickness ratios of plate elements are provided to classify the section under a particular class.

4. Only plastic and compact sections can be used if limit state design is followed and only plastic sections can be used in mechanism-forming indeterminate frames.

5. Slender sections is to be avoided even in elastic design. But they are invariably used in cold-formed construction for reasons of economy. In this case, caution is required in predicting their ultimate capacities.